- Phone:

- 0086-13506565739

- Tel:

- 0086-577-66851569

- E-mail:

- [email protected]

- Address:

- Songjiadai Industrial Estate,Feiyun Town,Ruian City,Wenzhou,Zhejiang,China

Features

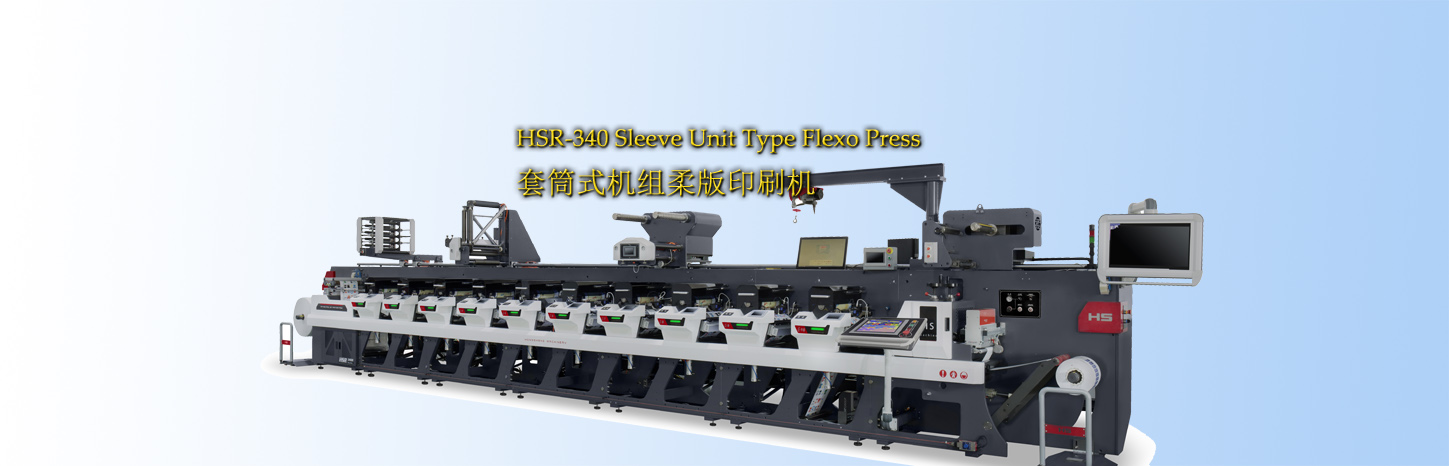

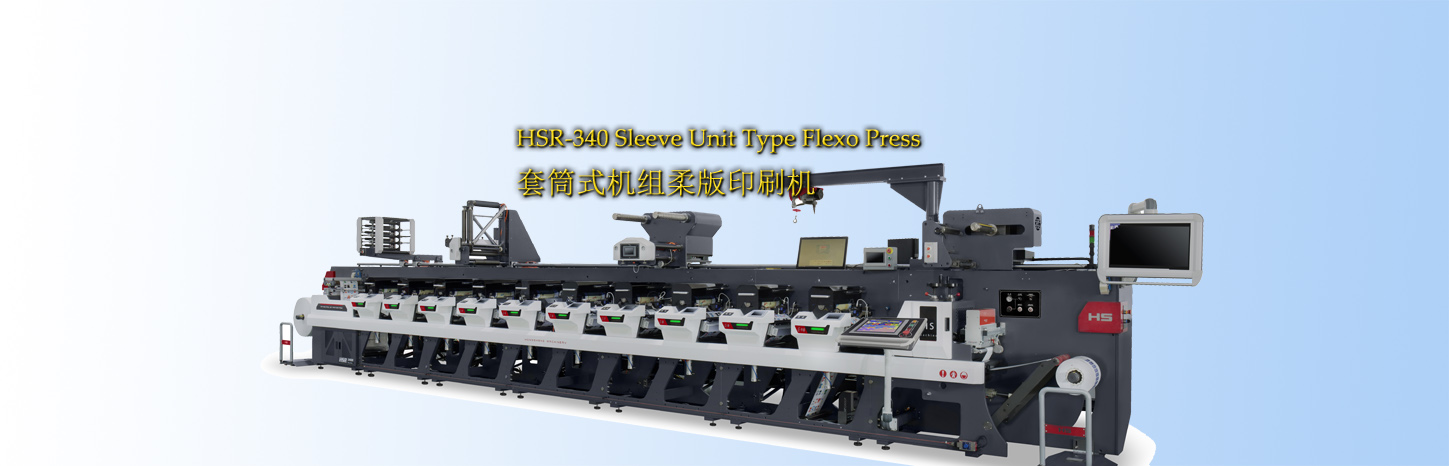

The HSR Serial unit flexo presses is our newest machine which aimed to produce high quality label with high speed and IML label function . the large 1050mm unwinding with servo motor keeps the roller running stable and auto stop on the end .

This machine compact size and short web path keeps wastage of material

The full machine adopt all servo motor , there all total 25 pcs servo motor , unwinding unit , rewinding unit ,two nipping roller ,8 set of printing unit ,2 set of die cutting unit ,matrix rewinding unit which keep the tension of film or paper smoothly and stable.

|

Max.Web width |

350/460/530/670mm |

|

Max.Printing width |

340/450/520/660mm |

|

Max.Unwind Diameter |

1050mm |

|

Max.Rewind Diameter |

1050mm |

|

Max.printing speed |

200m/min |

|

Printing Precision accuracy |

|

|

Rang of printing |

9.5”-24” |

|

Max.label die cutting speed |

150m/min |

|

Pre –registration |

Semi |

|

Auto registration |

Servo motor with color sensor |

|

Material |

All Paper material ,Aluminum material ,unsupport film and shrink |

|

Thickness of material |

0.02mm—0.35mm |

|

Power |

380V 50/60HZ |

|

Air Supply |

0.8KPA |

|

60A |

|

|

Machine Weight |

About 10000KG depend on quantity of unit |

|

Start machine power |

|

|

high speed power |

|

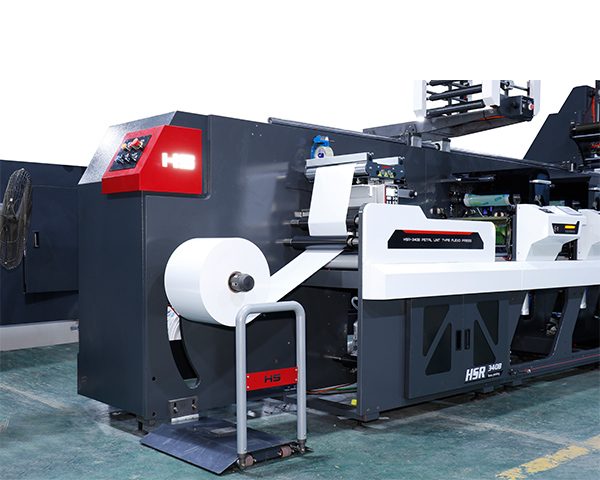

UNWINDING UNIT

? Maximum diameter of unwinding is 1050mm adopt pneumatic cylinder for loading and unloading

? Air expanding shaft for 3 "

? Servo motor for unwinding

? Paper cutting platform for pneumatic clamping paper

? Electronic Web aligner for accurate alignment of the Web (BST German)

? Pneumatic components adopted by Airtac

? Corona device effectively increases the amount of ink on film (optional)

? Removing static electricity from material surface with electrostatic device(optional)

? Dust removal from the surface of raw material with dust removal device(optional)

SPLICE TABLE (ON WEB GUIDING)

? Pneumatic controls splice table for east splicing and web jointing

? Individual pneumatic controls for each splice bar

? Splice table with cutter support slot

Nipping driver

? Servo driver controls the infeed and out with auto tension for accurate tension of substrate into printing

? The nipping roller works with pneumatic cylinder and PU roller

Printing unit

? Wide range from 10” to 24” of plate roller

? Teflon technology for ink tray which is easy to clean ,ink roller ,impression roller with tolerance as +/- 0.01mm and ceramic anilox from China

? Quick change the ink tray and pneumatic lock

? Quick lock and unload for plate roller without using tools

? NO Helical gears for plate roller and ceramic anilox ,etc

? A Auxiliary motor for anilox keeps running while the press stops to avoid drying the ink on the anilox surface especially when we use water base ink

? Surface hard aluminum guide roller

? Special structure of scraping blade ensure the cleaning of the surface of anilox

? Turn bar on the rail can move across the printing units

? monitor on the end of printing unit can inspect the registration of printing (BST)

? The Impression roller is also a Chiller Drum which in order to cool while printing ,that will not make the material shrink.

? 2 ton capacity Chiller with water circulation system

? Beside saving power ,the LED UV which this machine use also have Chiller connection

? Hot air drying with individual heaters and blowers for optimum usage (Optional)

? Delam -Relam Unit with enough roller fo proper control of web during Delam to print up to 4 colors on back of web (glue side)

? Pre-Registration system to set the printing cylinders to near registation before start of printing ,this is also why this machine can print with shrink film

? Auto-Registration system used by this machine because of plate roller and impression roller adopt its own independent servo motor

? Lateral position of printing unit fine turning by motor

Cold Stamping Device

? Cold Foil Unit on rail for movable across printing units

? Magnetic power and clutch control the Cold stamping device

? Pneumatic expanding shaft for unwinding and rewinding

Rotary die cutting

? 1 set of die cutting station

? total 3 rollers die cutting system for die cutting on the front or back side of the web by changing the anvil roller and magnetic roller

? A crane assembled near the die cutting station load and unload the magnetic cylinder

Matrix rewinding system

? Max. waste rewinding diameter 900mm

? Pneumatic expand air shaft 3”

? A servo driver controls the running of matrix rewinding

Rewinding device

? Maximum diameter 1050mm

? Air expanding shaft for 3 “

? Pneumatic cylinder for loading and unloading